Understanding both sides of the Buy/Sell Process

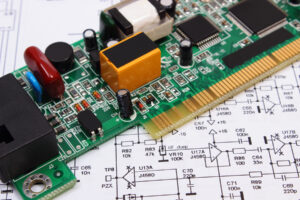

It would be nice if you could google an accurate PCB Assembly price. However, board specifications and manufacturing requirements differ, not to mention the volatile market conditions of COTS. Many self-service quote modules currently used on websites do a decent job on pricing the bare boards, however they fall short when pricing Turnkey assemblies. Eventually, the gaps between what was quoted online and the actual PCBA manufacturing cost surface. This ultimately happens after the review of your Gerber files and Bill of Material. At this point you have invested a lot of time with less than a favorable result. What’s worse is that you may have already plugged these estimates into your product development plan requiring you to back track.

We believe the fit between two companies is the basis of a success relationship. Needs and processes are not always in alignment between customers and suppliers. Unfortunately, these are not always uncovered until after a project gets underway. This is not the best time to figure this out. Making sure the OEM and the Contract Manufacturer are on the same page before embarking in the quote process is the start of a transparent relationship and ultimately saves time. Understanding the process from both the buyer and seller perspective up front, will make for a successful relationship that’s a win-win with long term success.

Highlighted below are the items Altek discusses when working with a prospective customer. Not only are these important conversations for Altek to have with its customers, but important points to consider when evaluation any Contract Manufacturer. Getting this information on the table helps determine the customer/supplier fit before proceeding with the quote process.

Highlighted below are the items Altek discusses when working with a prospective customer. Not only are these important conversations for Altek to have with its customers, but important points to consider when evaluation any Contract Manufacturer. Getting this information on the table helps determine the customer/supplier fit before proceeding with the quote process.

Valuable information to share:

• Product Life (new development, prototype only, full production, EOL)

• Overall volume, shipment/delivery needs, is Kanban part of the long-term requirement?

•Are you looking for full turnkey, consignment, or a partial consignment partner?

• Is lowest price always the deciding factor?

• What quality acceptance metrics are you receiving today? Where do you want to be?

• What are the on-time delivery metrics from your current supplier? Does this meet your needs?

• What type of Engineering support are you currently receiving, and do you need more?

• Do you need DFM support for new product designs?

• How important is the physical distance from your Contract Manufacturer to your facility?

• Are you looking for an additional supplier or replacing a current one?

• What “voids” do you need filled?

• Is this part of reshoring your business to secure your supply chain?

Information to ask of a prospective supplier:

• What are the most valuable things your company brings to the table?

• Request references and check them.

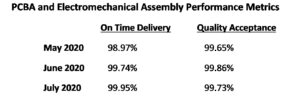

• Ask for the suppliers 12-month rolling average for On-Time-Delivery and Quality Acceptance rates.

• Check the manufacturers financial stability.

• What is your Business Continuity – Disaster Recovery plan?

• What is your supply chain management process?

• What certifications does your company have?

• Share your companies QMS process/program.

• How long have your key customers been with you?

These items are important pieces of the Total cost of ownership evaluation process of a new supplier. This information exchange process works, and it will allow you to eliminate sub-standard suppliers before starting the bid cycle. None of us have time to waste as referenced by Benjamin Franklin quote…“Remember time is money”!

You can read more about Total Cost of Acquisition at the link below:

Terry Weiner, Senior Consultant, California Manufacturing Technology Consulting (CMTC) states that – “Traditional costing methods such as Purchase Price Variance (PPV) typically miss between 20 to 40 percent of the actual costs of acquisition.”

https://www.cmtc.com/blog/bid/156131/The-Importance-of-Total-Cost-of-Ownership-TCO

more than Manufacturing Defect Analysis (MDA) testing. Its usage and range of capabilities has significantly expanded in recent years. OEMs competing for market share based on quality and price need to understand when it makes sense to add flying probe to your PCB assembly requirement.

more than Manufacturing Defect Analysis (MDA) testing. Its usage and range of capabilities has significantly expanded in recent years. OEMs competing for market share based on quality and price need to understand when it makes sense to add flying probe to your PCB assembly requirement.

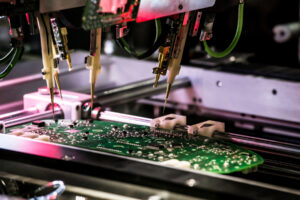

The engineering department may be participating in the design of a new product, providing DFM support or creating custom solutions for obsolete components.

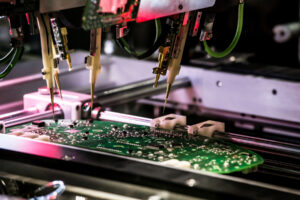

The engineering department may be participating in the design of a new product, providing DFM support or creating custom solutions for obsolete components. The manufacturing staff with extensive on hands training and eagle eyes oversee the product build. There are hands on every day overseeing each operation, performing inspection and testing of your product prior to shipment.

The manufacturing staff with extensive on hands training and eagle eyes oversee the product build. There are hands on every day overseeing each operation, performing inspection and testing of your product prior to shipment. What’s today’s conversation like?

What’s today’s conversation like? Working with a diverse group of part suppliers to ensure components availability?

Working with a diverse group of part suppliers to ensure components availability?